Flat belt conveyor design calculations consist 1.Conveyor belt speed 2. Roller diameter 3.Conveyor capacity 4. Conveyor power calculations 5.Conveyor live load kg per meter 6. belt width.

What Is Material Handling?

Conveyors are just one subset of the much larger group of material handling equipment. Through the proper application and use of material handling equipment, we try to minimize or even eliminate the manual handling of material. Material handling is all about movement; raw materials, parts, boxes, crates, pallets, and luggage must be moved from one place to another, from point A to point B, ideally in the most efficient manner. The material being handled is virtually limitless in size, shape, weight, or form.

Material can be moved directly by people lifting and carrying the items or using hand carts, slings, and other handling accessories. Material can also be moved by people using machines such as cranes, forklift trucks, and other lifting devices. Finally, material can be moved using automated equipment specifically designed for mechanically handling the items such as robots and conveyors. “Material handling is the art and science associated with providing the right materials to the right place in the right quantities, in the right condition, in the right sequence, in the right orientation, at the right time, at the right cost using the right methods.

What Are the Major Objectives of Conveyor Application?

Reduce actual manual handling to a minimum.

Perform all handling operations at the lowest reasonable cost.

Eliminate as many manual operations as possible.

Ease the workload of all operators.

Improve ergonomic considerations for each operator.

Improve workflow between operations.

Provide routing options for intelligent workflow.

Increase throughput.

Carry product where it would be unsafe to do so manually.

Components of belt conveyor:

1.Conveyor frame- It is structure which support and maintains the alignments of idlers, pulleys and drives. There are several prominent frame design types.

a) Most common is a welded steel frame.

b) Aluminum extrusion frame which is popular for flexibility.

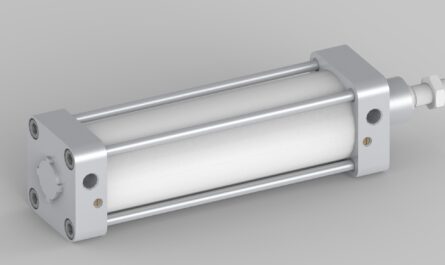

2.Drive unit- Which imparts power through one or more pulleys or rollers to move belt and its loads. Generally, drive unit is electric motor with gearbox.

3.Belt- The belt, which forms the moving and supporting surface on which the conveyed material is placed. The belt not only carries material, but also transmit the pull. It is the tractive element. Types of various belts 1. Flat belt, 2.Modular belt, 3. Cleated belt, 4.V belt, 5.Timing belt.

4.Drive pulley or Drive roller

5.Driven pulley or Driven roller

6. Take up unit- The take-up device in a conveyor belt system has three major functions:

a)To establish and maintain a predetermined tension in the belt.

b) Remove the accumulation of slack in the belt at start-up or during momentary overloads, in addition to maintaining the correct operating tension.

c) To provide sufficient reserve belt length to enable re-splicing, if necessary

7.Electric control panel- Electrical control panel has all electrical components like MCB’s, on off switch, and VFD.

THE PARAMETERS FOR BELT CONVEYOR DESIGN:

1.Drive roller Diameter (mm)

2.Belt length (mm)

3.Maximum loading Capacity (Tonnes /Hr.)

4. Belt width (mm)

5.Conveyor speed(m/s)

6.Material per unit length(kg/m)

7.Motor (Kw)

Input data or Considerations or Assumptions:

While any conveyor design you have some input data like center distance, required belt speed, type of material and size of material, conveyor capacity i.e. kg/s or Tonnes per hour.

If there is no any data given you have to consider it.

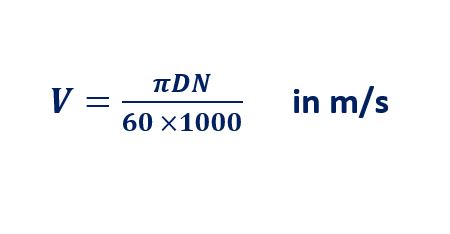

1.Roller Diameter and speed of conveyor

Similarly, By rearranging speed equation diameter of the drive pulley is,

$$D=\frac{V\times60\times1000}{\mathrm\pi\times\mathrm N}$$

Where,

V – Belt speed in m/s

D – Roller diameter (mm)

N – No of revolutions per minute(rpm).

2.Belt Length

a) When one pulley is larger than other.

$$L=2C+\frac{\mathrm\pi(\mathrm D+\mathrm d)}2+\frac{{(D-d)}^2}{4C}$$

b) Similarly, When both pulleys having same diameter.

$$L=2C+\frac{\mathrm\pi(\mathrm D+\mathrm d)}2$$

Where,

L – Belt Length(mm)

D – Large pulley diameter ( mm)

d – Small pulley diameter (mm)

C – Center distance (mm)

3.Belt width

Minimum belt width may be influenced by loading or transfer point requirements, or by material lump sizes. Standard belt widths are 400, 450, 500, 600, 650, 750, 800, 900, 1000, 1050, 1200, 1350, 1400, 1500, 1600, 1800, 2000 and 2200.

Also, you can calculate belt width as,

$$B_{min}=1.11\lbrack{\{\frac Q{c\times v}\}}^\frac12+0.05\rbrack$$

Where,

B min – Minimum belt width required.

Q-Conveyor capacity tonnes/hr

v- Belt speed meter/ second

c-Factor for the type of idler

=240,for flat belt

=460, for trough angle of 20

=510, for trough angle of 25

=540, for trough angle of 30

4.Capacity of conveyor (Q ) Tonnes/hr.

The rate at which material is being carried out by the conveyor.

Capacity Q = 3.6 X Load cross sectional area perpendicular to belt (m^2) X Belt speed (m/s) X Material density (kg/m^3)

= 3.6 x A x V x ρ Tonnes/hr.

5.Mass of material per unit length M (kg/m)

$$M=\frac{\mathrm Q}{3.6\times V}$$

Where,

Q – Capacity of conveyor in Tonnes/hour

V – Conveyor belt speed in m/s

6.Belt power calculations in conveyor design

Required Power = Belt pull x Belt speed

$$Power=\frac{F\times V}{1000}\;Kw$$

Where,

P – Power rating in (Kw)

V – Velocity of belt (m/s).

F – Total tangential for at the periphery of drive pulley(N).

7. Tangential force on periphery of drive pulley F (N)

$$F=\mu\times g\times(M_b+M_r+M_m)$$

Where,

Mb – Total mass of belt (kg)

Mr – Total mass of rollers (kg)

Mm – Mass of material over entire length of conveyor (kg)

g – Acceleration due to gravity(m/s^2)

μ – Coefficient of friction generally in between 0.1 to 0.4

You also like to read:

- Mechanical design engineer interview questions and answers for freshers.

- Mechanical engineering interview questions and answers for freshers.

- Top 30 HR interview questions and answers for freshers all jobs.

- How to select right bearing for your application.

- Catia v5 interview questions and answers.

Flat belt conveyor design calculations with practical application”

Dear sir,

I need the full catalog of above topic. I need complete calculations for Flat belt conveyor design.

Thanks.

Kamal