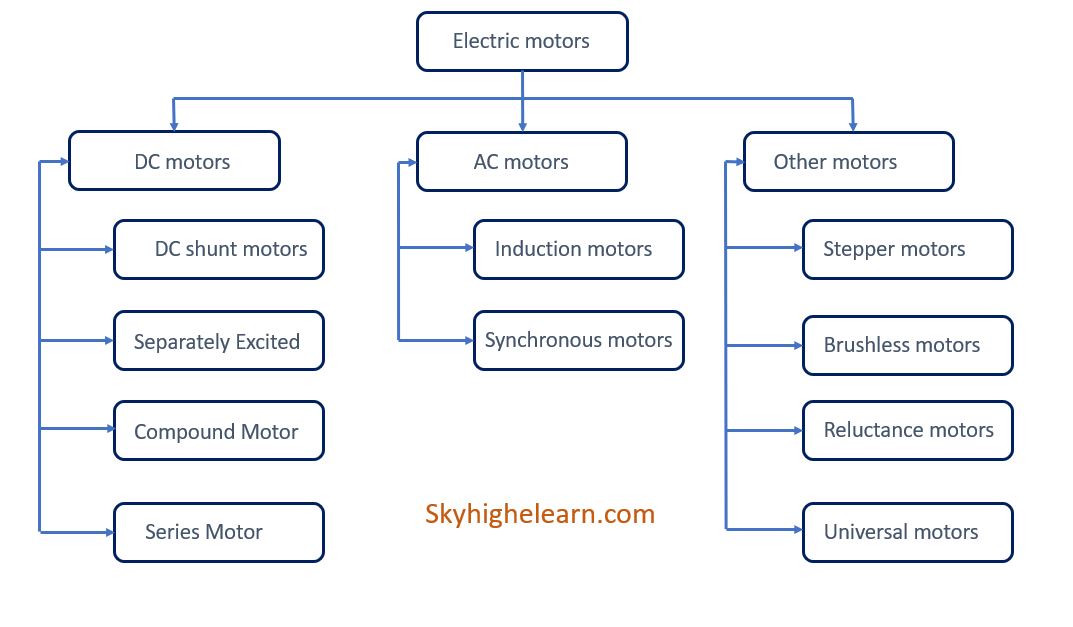

Different types of electric motors used for industrial applications

Electric motors are the devices which converts electrical energy into mechanical energy i.e rotational motion and are basically classified into two major categories: DC (Direct Current) and AC (Alternating Current). Within these categories there are various types of motors, each type offering unique abilities that suit them well for specific applications.

There are different aspects to consider while selecting induction motor for your application such as mechanical, operational and environmental issues.

AC Motors

An alternating current motor is a device which convert alternating current (electrical energy) into the mechanical power i.e rotational motion.

Ac motors has two main parts stator and rotor. Rotor is the rotary part of motor and stator is stationary part of motor. It can be three phase or single phase. Ac motors has wide range of application from household small appliance power generation to bulk power generation for industrial applications.

Classification of AC motors

- Synchronous motor

- Asynchronous motor or Induction motor

Synchronous motor

It is the AC motor in which shaft rotation is synchronised with frequency of input supply current. Also synchronous motor has fixed speed.

Induction motor

Induction motors works on the principle of electromagnetic induction and is also known as asynchronous motor.It is in simple design, low cost and minimum maintenance. It is most commonly used electric motors in various applications. These are called asynchronous electric motors because it always runs slower than synchronous speed. Induction motor can be a single phase or three phase.

Applications: Fans, Grinder, Centrifugal pump, conveyors, Compressors and Lathe machine etc.

DC Motors

In simple words DC motor is a device which convert direct current (electrical energy) into the mechanical energy. Similarly, a device which converts D.C power into mechanical power is known as DC electric motor.

DC motor operation is based on the principle that when a current carrying conductor is kept in a magnetic field, the conductor develops a tendency to move and experiences a mechanical force. The direction of this mechanical force is given by Fleming’s left-hand rule.

The types of DC motor mainly include

Permanent magnet direct current motor

In these types permanent magnet is used to generate magnetic field.

Applications : Air conditioners, Automobile starters, Wipers etc.

Separately excited direct current motor

A motor whose field magnet is excited by current supplied from external source.

Application : Actuators.

Shunt wound direct current motor

In these types field windings and armature windings are connected in parallel. And used where stable speed is required.

Applications : Lathe machines, Fan, Conveyors.

Series wound direct current motor

In these types field windings and armature windings are connected in series. It can develop large torque and can be operated at low speed.

Applications: Industrial heavy cranes and Winches.

Short shunt Direct Current motor

In the shunt field winding is connected with the armature winding and that is in parallel. The field coil, which is in series, is entirely exposed to current before being split up into the armature.

Long shunt Direct Current motor

In these shunt field winding is connected in parallel with the both series field coil and armature which are again connected with each other in series.

Differential compound DC motor

It has low starting torque and has constant speed, but speed is very high at no load condition.

Applications : Reciprocating machines, Presses and Agitator etc.